Energy is added

to the gas stream in the combustor, where fuel is mixed with air and ignited.

In the high pressure environment of the combustor, combustion of the fuel

increases the temperature. The products of the combustion are

forced into the turbine section. There, the high velocity

and volume

of the gas flow is directed through a nozzle over the

turbine's blades, spinning the turbine which powers the compressor and, for

some turbines, drives their mechanical output. The energy given up to the

turbine comes from the reduction in the temperature and pressure of the exhaust

gas.

Friday, 18 December 2015

GAS TURBINE POWER PLANT?

Thursday, 17 December 2015

Cooling system of nuclear power plant?

Cooling system

A cooling system

removes heat from the reactor core and transports it to another area of the

plant, where the thermal energy can be harnessed to produce electricity or to

do other useful work. Typically the hot coolant will be used as a heat source

for a boiler,

and the pressurized steam from that boiler will power one or more steam

turbine driven electrical generators.

Flexibility

of nuclear power plants

It is often claimed that

nuclear stations are inflexible in their output, implying that other forms of

energy would be required to meet peak demand. While that is true for the vast

majority of reactors, this is no longer true of at least some modern designs.

Nuclear plants are routinely used in load following mode on a large scale in

France. Unit A at the German Biblis Nuclear Power Plant is designed

to in- and decrease his output 15 % per minute between 40 and 100 % of it's nominal

power. Boiling water reactors normally have load-following capability, implemented

by varying the recirculation water flow.

Nuclear reactor technology?

When a relatively large fissile atomic nucleus (usually uranium-235or plutonium-239)

absorbs a neutron,

a fission of the atom often results. Fission splits the atom into two or more

smaller nuclei with kinetic

energy (known as fission

products) and also releases gamma

radiation and free neutrons. A portion of these neutrons may later be absorbed by other fissile atoms and

create more fissions, which release more neutrons, and so on.

This nuclear chain reaction can be controlled

by using neutron poisons and neutron moderators to change the portion of

neutrons that will go on to cause more fissions. Nuclear reactors generally have automatic and manual systems to shut the

fission reaction down if unsafe conditions are detected.

Three nuclear powered ships, (top to bottom)

nuclear cruisers USS Bainbridge and USS Long Beach with USS Enterprise the first nuclear powered

aircraft carrier in 1964. Crew members are spelling out Einstein's

mass-energy equivalence formula E = mc2

on the flight deck.

There are many different reactor designs, utilizing different fuels and

coolants and incorporating different control schemes. Some of these designs

have been engineered to meet a specific need. Reactors for nuclear

submarines and large naval ships, for example, commonly use highly enriched uranium as a fuel. This

fuel choice increases the reactor's power density and extends the usable life

of the nuclear fuel load, but is more expensive and a greater risk to nuclear

proliferation than some of the other nuclear fuels.

A number of new designs

for nuclear power generation, collectively known as the Generation IV reactors, are the subject of

active research and may be used for practical power generation in the future.

Many of these new designs specifically attempt to make fission reactors

cleaner, safer and/or less of a risk to the proliferation of nuclear weapons. Passively safe plants (such as the ESBWR) are available to be

built and other designs that are believed to be nearly fool-proof are being

pursued. Fusion reactors, which may be viable in the

future, diminish or eliminate many of the risks associated with nuclear

fission. There are trades to be made between safety, economic and technical

properties of different reactor designs for particular applications.

Historically these decisions were often made in private by scientists,

regulators and engineers, but this may be considered problematic, and since

Chernobyl and Three Mile Island, many involved now consider informed consent

and morality should be primary considerations.

Monday, 14 December 2015

NUCLEAR POWER PLANT?

Nuclear power is

the use of sustained Nuclear fission to generate heat and do useful

work. Nuclear Electric Plants, Nuclear Ships and Submarines use controlled

nuclear energy to heat water and produce steam, while in space,

nuclear energy decays naturally in a radioisotope thermoelectric generator.

Scientists are experimenting with fusion energy for future generation, but these experiments do not currently generate

useful energy.

Nuclear power provides about 6% of the world's energy and 13–14% of the

world's electricity, with the U.S., France, and Japan together accounting for about 50% of

nuclear generated electricity. Also, more than 150 naval vessels using nuclear propulsion have been built.

Just as many

conventional thermal power stations generate

electricity by harnessing the thermal

energy released from burning fossil fuels,

nuclear power plants convert the energy released from the nucleus of an atom,

typically via nuclear fission.

Advantages and Disadvantages of diesel power plants?

Advantages of diesel power plants

- More efficient than thermal plant

- Design, Layout etc are simple and cheap

- Part load efficiency is very high

- It can be started quickly

- Simple & easy maintenance

- No problem with fuel & dust handling

- It can be located in the heart of town

- Less cooling water required.

- There is a limitation for size of a diesel engine

- Life of plant is comparatively less

- Noise pollution is very high

- Repair cost is very high

- High lubrication cost

DIESEL POWER PLANT?

Diesel power

plants produce power from a diesel engine. Diesel electric plants in the range

of 2 to 50 MW capacities are used as central stations for small electric supply

networks and used as a standby to hydro electric or thermal plants where

continuous power supply is needed. Diesel power plant is not economical

compared to other power plants.

The diesel power plants are cheaply used in the fields mentioned below.Peak

load plants

- Mobile electric plants

- Standby units

- Emergency power plants

- Starting stations of existing plants

- Central power station etc.

Engine is the heart of a diesel power plant. Engine

is directly connected through a gear box to the generator. Generally two-stroke

engines are used for power generation. Now a days, advanced super & turbo

charged high speed engines are available for power production.

Air inlet is arranged outside the engine room. Air

from the atmosphere is filtered by air filter and conveyed to the inlet manifold

of engine. In large plants supercharger/turbocharger is used for increasing the

pressure of input air which increases the power output.

This includes the silencers and connecting ducts.

The heat content of the exhaust gas is utilized in a turbine in a turbocharger

to compress the air input to the engine.

Fuel is stored in a tank from where it flows to the

fuel pump through a filter. Fuel is injected to the engine as per the load

requirement.

This system includes water circulating pumps,

cooling towers, water filter etc. Cooling water is circulated through the

engine block to keep the temperature of the engine in the safe range.

Lubrication system includes the air pumps, oil

tanks, filters, coolers and pipe lines. Lubricant is given to reduce friction

of moving parts and reduce the wear and tear of the engine parts.

There are three commonly used starting systems, they are;

1) A petrol driven auxiliary engine,

2) Use of electric motors,

3)Use of compressed air from an air compressor at a pressure of 20 Kg/cm”

The function of a governing system is to maintain

the speed of the engine constant irrespective of load on the plant. This is

done by varying fuel supply to the engine according to load.

LAYOUT OF HYDEL POWER PLANT?

Hydroelectric

power plants convert the hydraulic potential energy from water into electrical

energy. Such plants are suitable were water with suitable head are

available. The layout covered in this article is just a simple one and only

cover the important parts of hydroelectric plant.The different parts

of a hydroelectric power plant are

Dams are structures built over rivers to stop the water flow and form a

reservoir.The reservoir stores the water flowing down the river. This water is

diverted to turbines in power stations. The dams collect water during the rainy

season and stores it, thus allowing for a steady flow through the turbines

throughout the year. Dams are also used for controlling floods and irrigation.

The dams should be water-tight and should be able to withstand the pressure

exerted by the water on it. There are different types of dams such as arch

dams, gravity dams and buttress dams. The height of water in the dam is called head

race.

A spillway as the name suggests could be called as a way for spilling of water

from dams. It is used to provide for the release of flood water from a

dam. It is used to prevent over toping of the dams which could result in damage

or failure of dams. Spillways could be controlled type or uncontrolled

type. The uncontrolled types start releasing water upon water rising above a

particular level. But in case of the controlled type, regulation of flow is

possible.

Penstocks are pipes which carry water from the reservoir to the turbines inside

power station. They are usually made of steel and are equipped with gate

systems.Water under high pressure flows through the penstock. A tunnel serves

the same purpose as a penstock. It is used when an obstruction is present

between the dam and power station such as a mountain.

Surge tanks are tanks connected to the water conductor system. It serves the

purpose of reducing water hammering in pipes which can cause damage to pipes.

The sudden surges of water in penstock is taken by the surge tank, and when the

water requirements increase, it supplies the collected water thereby regulating

water flow and pressure inside the penstock.

Power station contains a turbine coupled to a generator. The water brought to

the power station rotates the vanes of the turbine producing torque and

rotation of turbine shaft. This rotational torque is transfered to the

generator and is converted into electricity. The used water is released through

the tail race. The difference between head race and tail race is called

gross head and by subtracting the frictional losses we get the net head

available to the turbine for generation of electricity.

What is meant by Cooling Water Circuit?

The quantity of

cooling water required to cool the steam in a thermal power plant layout is

significantly high and hence it is supplied from a natural water source like a

lake or a river. After passing through screens that remove particles that can

plug the condenser tubes in a thermal power plant layout, it is passed through

the condenser where the steam is condensed. The water is finally discharged

back into the water source after cooling. Cooling water circuit can also be a

closed system where the cooled water is sent through cooling towers for re-use

in the power plant. The cooling water circulation in the condenser of a thermal

power plant layout helps in maintaining a low pressure in the condenser all

throughout. All these circuits are integrated to form a thermal power plant layout that

generates electricity to meet our needs.

What is meant by Feed Water and Steam Circuit?

The steam produced in

the boiler is supplied to the turbines to generate power. The steam that is

expelled by the prime mover in the thermal power plant layout is then condensed

in a condenser for re-use in the boiler. The condensed water is forced through

a pump into the feed water heaters where it is heated using the steam from

different points in the turbine. To make up for the lost steam and water while

passing through the various components of the thermal power plant layout, feed

water is supplied through external sources. Feed water is purified in a

purifying plant to reduce the dissolve salts that could scale the boiler tubes.

What is meant by Air and Gas Circuit?

Air from the

atmosphere is directed into the furnace through the air preheated by the action

of a forced draught fan or induced draught fan. The dust from the air is

removed before it enters the combustion chamber of the thermal power plant

layout. The exhaust gases from the combustion heat the air, which goes through

a heat exchanger and is finally let off into the environment.

What is meant by Coal and Ash Circuit?

Coal and Ash circuit

in a thermal power plant layout mainly takes care of feeding the boiler with

coal from the storage for combustion. The ash that is generated during combustion

is collected at the back of the boiler and removed to the ash storage by scrapconveyors. The combustion in the Coal and Ash circuit is controlled by

regulating the speed and the quality of coal entering the grate and the damper

openings.

Main circuits of thermal power plant ?

The four main circuits one would come across in any thermal power plant layout are

-Coal and Ash Circuit

-Air and Gas Circuit

- Feed Water and Steam Circuit

- Cooling Water Circuit

What is meant by STEAM POWER PLANT?

A thermal power station

is a power plant

in which the prime mover is steam driven. Water is

heated, turns into steam and spins a steam turbine

which drives an electrical generator. After it passes

through the turbine, the steam is condensed

in a condenser and recycled to where it was heated;

this is known as a Rankine cycle. The greatest variation in the

design of thermal power stations is due to the different fuel sources. Some

prefer to use the term energy center because such facilities convert

forms of heat

energy

into electricity. Some thermal power plants also deliver heat energy for

industrial purposes, for district heating, or for desalination

of water as well as delivering electrical power. A large proportion of CO2

is produced by the worlds fossil fired thermal power plants; efforts to reduce

these outputs are various and widespread.

Sunday, 13 December 2015

PURPOSE OF HEAT EXCHANGER?

Suppose you have a gas central heating furnace (boiler) that heats hot-water radiators in various rooms in your home. It works by burning natural gas, making a line or grid of hot gas jets that fire upward over water flowing through a network of pipes. As the water pumps through the pipes, it absorbs the heat energy and heats up. This arrangement is what we mean by a heat exchanger: the gas jets cool down and the water heats up.

A heat exchanger is a device that allows heat from a fluid (a liquid or a gas) to pass to a second fluid (another liquid or gas) without the two fluids having to mix together or come into direct contact. If that's not completely clear, consider this. In theory, we could get the heat from the gas jets just by throwing cold water onto them, but then the flames would go out! The essential principle of a heat exchanger is that it transfers the heat without transferring the fluid that carries the heat.

heat exchanger is a device used to transfer heat between one or more fluids. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils andair flows past the coils, which cools the coolant and heats the incoming air.

Thursday, 10 December 2015

What is meant by Free Expansion?

Free expansion, as the name implies refers to the unrestrained expansion of a gas. Let as take an insulated tank having two compartments separated by a partition, say A and B. Let us assume that compartment A is filled with gas while B is having vacuum. If now the partition is removed and gas allowed to occupy the whole volume of tank, then the gas expands to fill the complete volume space. New pressure of gas will be lesser as compared to initial pressure of gas occupying them compartment A. A close look at the expansion process shows that the expansion due to removal of partition is unresisted expansion due to gas expanding in vacuum. This is also known as free expansion. The reverse of free expansion is impossible and so it is an irreversible process

What is meant by Hyperbolic process?

Hyperbolic process is the one in which product of pressure and volume remains constant during the process. The curve for such an expansion process is a rectangular hyperbola and hence this is known as hyperbolic expansion.

For a perfect gas PV/T= Constant, if T is also constant then it means that for a perfect gas the hyperbolic process shall also be isothermal process.

What is meant by Polytropic process?

Polytropic process is the most commonly used process in practice. In this, the thermodynamic process is said to be governed by the law PVn = constant where n is the index which can vary from – ∞ to + ∞. Figure 3.6 shows some typical cases in which the value of n is varied and the type of process indicated for different values of n. Thus the various thermodynamics processes discussed above are special cases of polytropic process.

What is meant by Adiabatic process?

An adiabatic process is the thermodynamic process in which there is no heat interaction during the process, i.e. during the process, Q = 0. In these processes the work interaction is there at the expense of internal energy. If we talk of adiabatic expansion then it shall mean that work is done at the cost of its own internal energy. The adiabatic process follows the law PVγ = constant where γ is called adiabatic index and is given by the ratio of two specific heats. Thus, it is obvious that adiabatic expansion shall be accompanied by the fall in temperature while temperature will rise during adiabatic compression.

What is meant by Constant temperature process or isothermal process?

Thermodynamic process in which the temperature remains constant is called constant temperature or isothermal process. In this case the gas or vapour may be heated at constant temperature and there shall be no change in internal energy. The work done will be equal to the amount of heat supplied, as shown ahead

What is meant By Constant volume process or isochoric process?

When a fluid undergoes a thermodynamic process in a fixed enclosed space such that the process occurs at constant volume, then the process is called constant volume process or isochoric process. Let us consider heating of a gas in fixed enclosure at constant volume. On p–V diagram this process is represented by a vertical line as shown in Fig. Area under the process line is zero which indicates that there is rise in pressure but there is no work done as there is no change in volume

What is meant Constant pressure process or isobaric process?

It refers to the thermodynamic process in which there is no change in pressure during the process. Such type of processes are also known as isobaric processes. To understand let us take a cylindrical vessel having gas in it. It has a piston above it. Piston is free to reciprocate in the cylinder. Under normal situation piston shall be subjected to atmospheric pressure. Now, let heat be added to cylinder from bottom of cylinder. Due to heat addition, presuming energy transfer taking place reversibly and system always remaining in equilibrium, the gas shall try to expand. Expansion of gas results in raising up of the piston and it attains a new state.

THERMODYNAMIC PROCESSES?

Thermodynamic processes can be precisely categorized as cyclic process and non-cyclic process. The cyclic process is the one in which the initial and final states are identical i.e. system returns to its initial states after occurrence of process. The non cyclic process is the one in which the initial and final states are different i.e. the occurrence of process is accompanied by the state change.

(i) Constant pressure process or isobaric process

(ii) Constant volume process or isochoric process

(iii) Constant temperature process or isothermal process

(iv) Adiabatic process

(vi) Hyperbolic process

Wednesday, 25 November 2015

What are all the waste heat management methods..?

- Combustion Air Preheating

- Load charge preheating

- Internal heat recycling- Cascading

Recovery of heat for plant utility supplement or auxiliary systems energy use in a plant or neighboring plants.

Can be used as retrofit for existing equipment.

What is Thermal expansion..?

When a substance is heated, its constituent particles move around more quickly and by doing so generally maintain a greater average separation.

Materials that contract with an increase in temperature are very

uncommon; this effect is limited in size, and only occurs within limited

temperature ranges. The degree of expansion divided by the change in

temperature is called the material's coefficient of thermal expansion and generally varies with temperature.

The term thermal expansion refers to the increase in size of an object as that object is heated. With relatively few exceptions, all objects expand when they are heated and contract when they are cooled. Perhaps the most important exception to this rule is water. Water contracts as it cools from its boiling point to about 39.2°F (4°C). At that point, it begins to expand as it cools further to its freezing point. This unusual effect explains the fact that ice is less dense than water.

The term thermal expansion refers to the increase in size of an object as that object is heated. With relatively few exceptions, all objects expand when they are heated and contract when they are cooled. Perhaps the most important exception to this rule is water. Water contracts as it cools from its boiling point to about 39.2°F (4°C). At that point, it begins to expand as it cools further to its freezing point. This unusual effect explains the fact that ice is less dense than water.

Monday, 23 November 2015

Principles of boiler..?

Boilers type

- Haycock and wagon top boilers

- Cylindrical fire-tube boiler

- Multi-tube boilers

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure (1–300 psi or 6.895–2,068.427 kPa) but, at pressures above this, it is more usual to speak of a steam generator.

What is radiator..?

Radiators are used for cooling internal combustion engines, mainly in automobiles but also in piston-engined aircraft, railway locomotives,motorcycles, stationary generating plants and other places where such engines are used.

The radiator is always a source of heat to its environment, although this may be for either the purpose of heating this environment, or for cooling the fluid or coolant supplied to it, as for engine cooling.

The radiator is always a source of heat to its environment, although this may be for either the purpose of heating this environment, or for cooling the fluid or coolant supplied to it, as for engine cooling.

What is brush electroplating..?

Electroplating

A closely related process is brush electroplating, in which localized areas or entire items are plated using a brush saturated with plating solution. The brush, typically a stainless steel body wrapped with a cloth material that both holds the plating solution and prevents direct contact with the item being plated, is connected to the positive side of a low voltage direct-current power source, and the item to be plated connected to the negative. The operator dips the brush in plating solution then applies it to the item, moving the brush continually to get an even distribution of the plating material. Brush electroplating has several advantages over tank plating, including portability, ability to plate items that for some reason cannot be tank plated (one application was the plating of portions of very large decorative support columns in a building restoration), low or no masking requirements, and comparatively low plating solution volume requirements. Disadvantages compared to tank plating can include greater operator involvement (tank plating can frequently be done with minimal attention), and inability to achieve as great a plate thickness.

What is electroplating..?

Electrochemical deposition

Electrochemical deposition is generally used for the growth of metals and conducting metal oxides because of the following advantages: (i) the thickness and morphology of the nano-structure can be precisely controlled by adjusting the electrochemical parameters, (ii) relatively uniform and compact deposits can be synthesized in template-based structures, (iii) higher deposition rates are obtained, and (iv) the equipment is inexpensive due to the non-requirements of either a high vacuum or a high reaction temperature.

Sunday, 22 November 2015

What is solar Air-Conditioning..?

Need of solar system

The demand for air-conditioning has been increasing through the last decade due to improved comfort and occurring higher temperatures. And with the higher demand come several problems: the extensive use of electrically driven cooling is leading to capacity straining power demand peaks in the summer and increase of green house emissions – either through leakage of cooling fluids or use of non-sustainable energy.

for more details click here

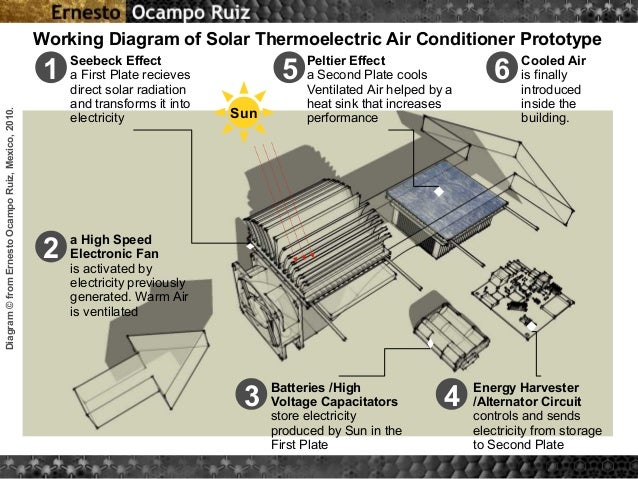

Functions of thermo-electric solar air conditioner....?

In the recent years, we

all are facing electricity crisis. It’s time to harness the renewable energy

resources of the nature.

The TEM operating principle is based on the

Peltier effect. The Peltier effect is a temperature difference created by

applying a voltage between two electrodes connected to a sample of

semiconductor material. One of the TEM sides is cooling and the other side is

heating. When a TE module is used, you must support heat rejection from its hot

side. If the temperature on the hot side is like the ambient temperature, then

we can get the temperature on the cold side that is lower (tens of Kelvin

degrees). The degree of the cooling is depended from the current value that is

leaking through a thermoelectric module. In a thermo-electric heat exchanger

the electrons acts as the heat carrier. The heat pumping action is therefore

function of the quantity of electrons crossing over the p-n junction.

Subscribe to:

Comments (Atom)